SPECifications

TECHNICAL ADVANTAGES

Machined side cuts considerably decrease overall wheel weight.

Further weight reduction is applied to the inner wall of the center hub and the side of the spokes, removing unnecessary material without affecting wheel strength.

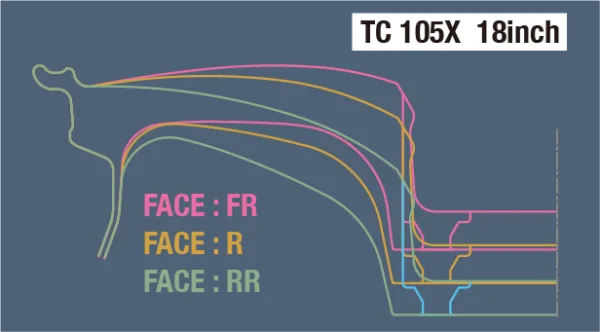

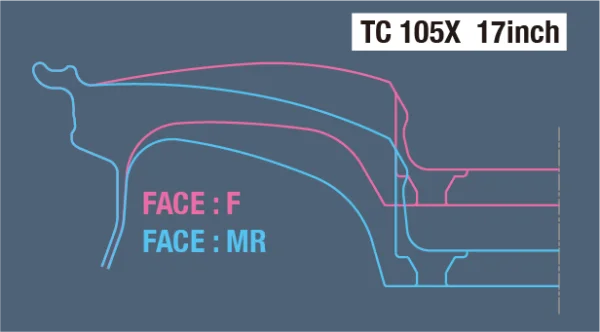

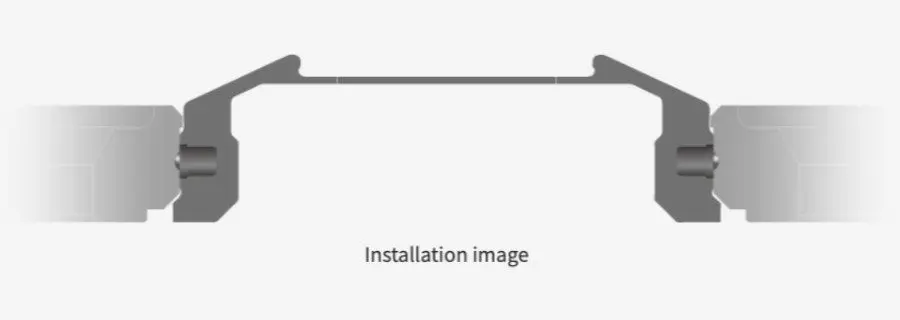

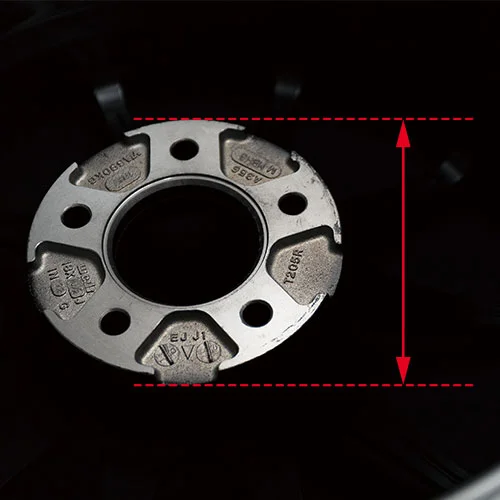

The upsized back-pad was designed to increase the contact area to hubs. It provides higher rigidity of the TC105X which enhance cornering performance and the steering stability.

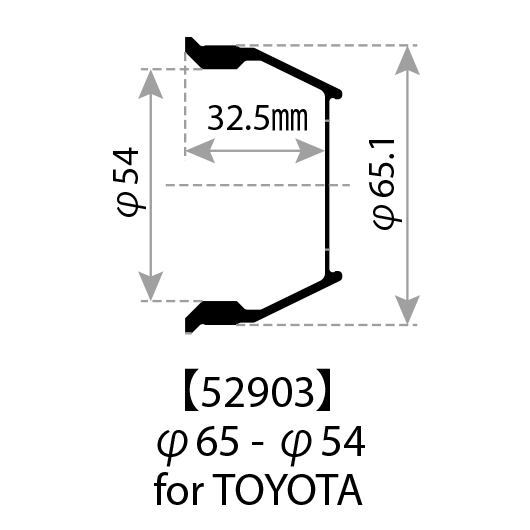

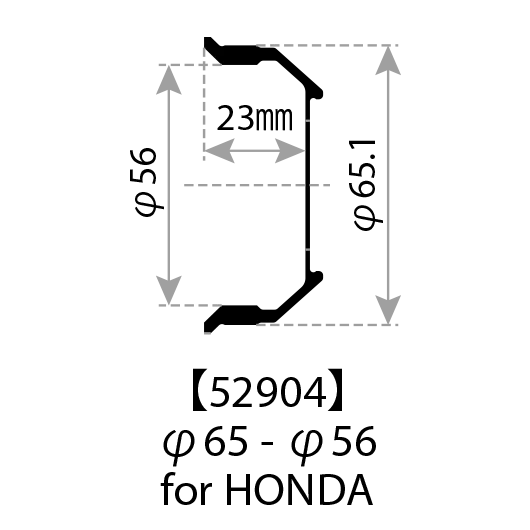

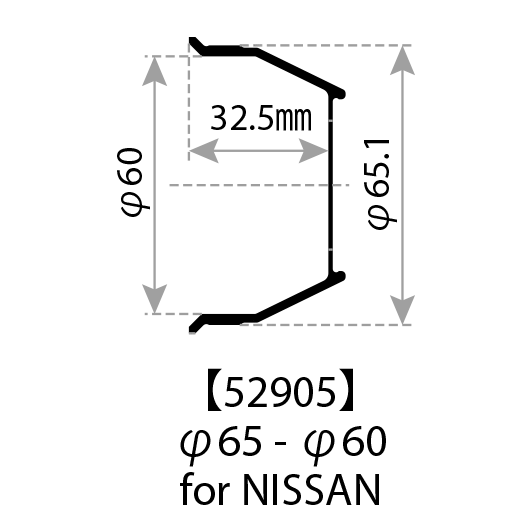

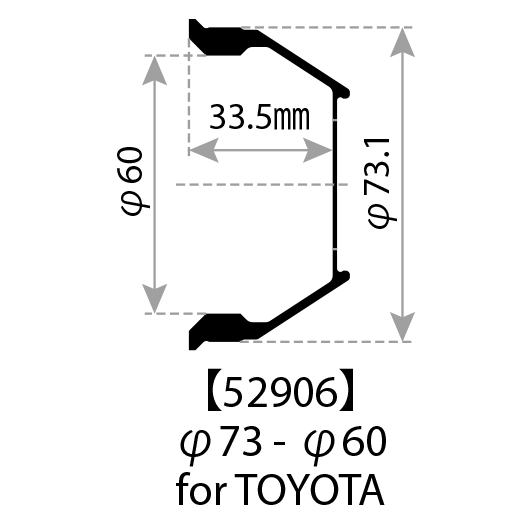

*The mounting surface vary according to size

The distinctive “N-FRAME” spoke reinforcement creates greater rigidity and impact dispersion.

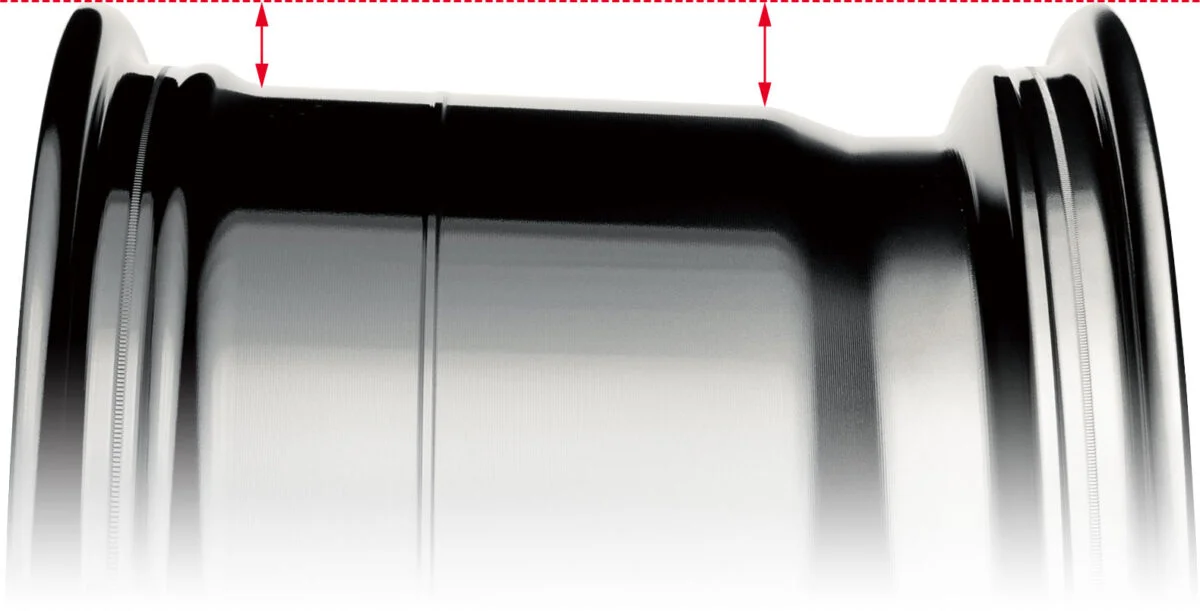

The anti-slip knurling reduces tire slippage under high torque and braking conditions.

Cutting the backside of the spoke further reduces weight without sacrificing strength.

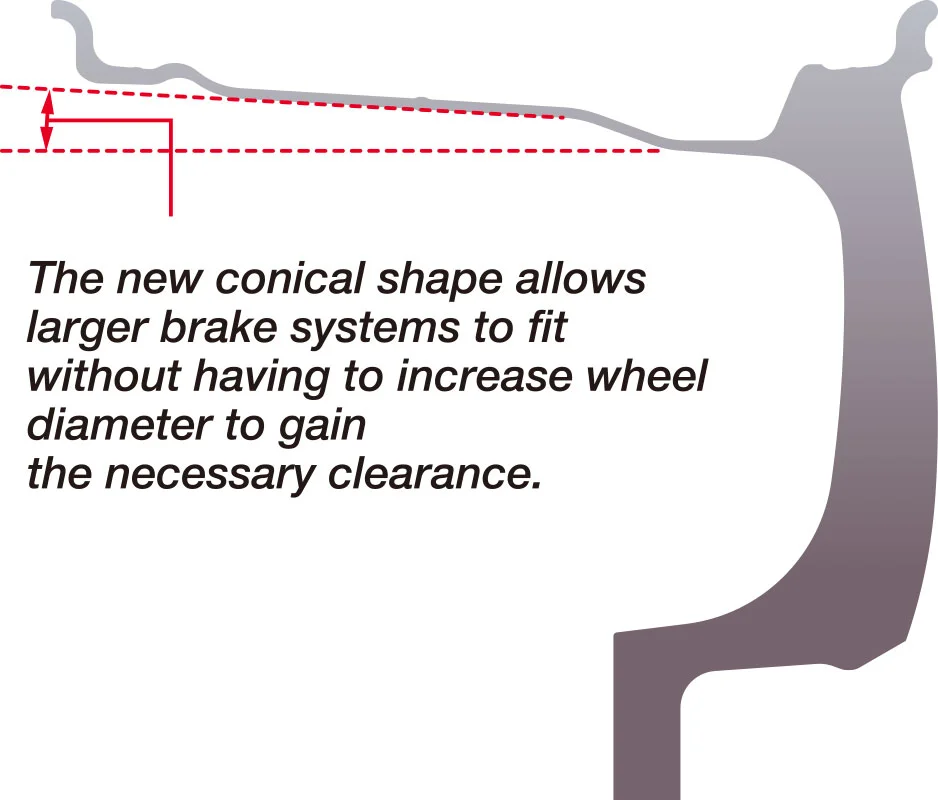

New conical barrel shape expands fitment options for big brake systems.

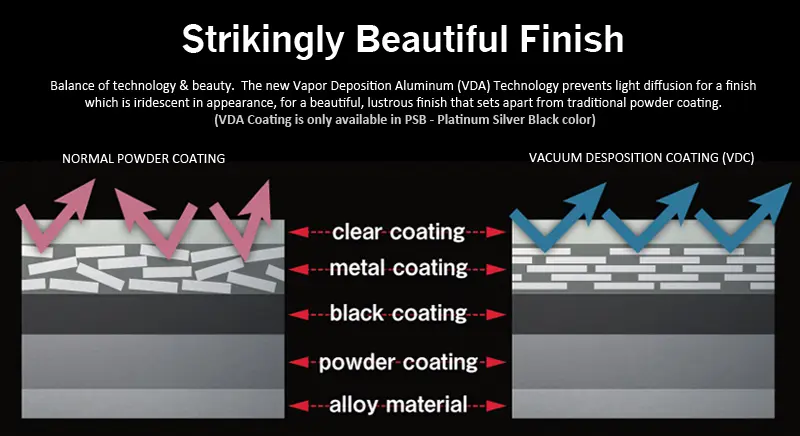

Brilliant Deep Coating

Coating composition

By employing Vacuum Deposition of aluminum paint, we've been able to achieve an overall paint thickness of 16nm (An industry first), compared to the previous standard of 50nm. This new paint technology creates a flatter & and smoother surface by reducing molecule overlapping, creating a shinier, metallic finish. Reflective properties in the paint allow for reduced heat retention with the addition of silica treatment. Chemical resistance has been improved to increase the durability of the finish.

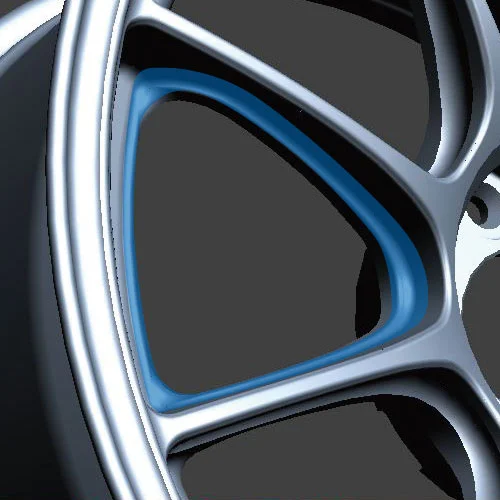

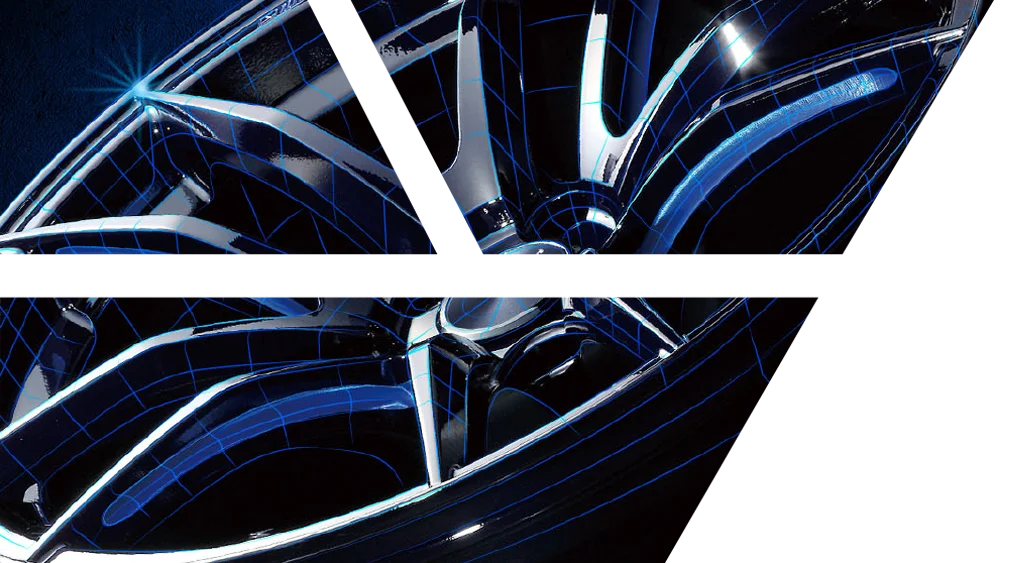

The brilliant coating and vacuum deposition technology creates a color tone that shifts with the viewing angle.

PRODUCT VIDEO

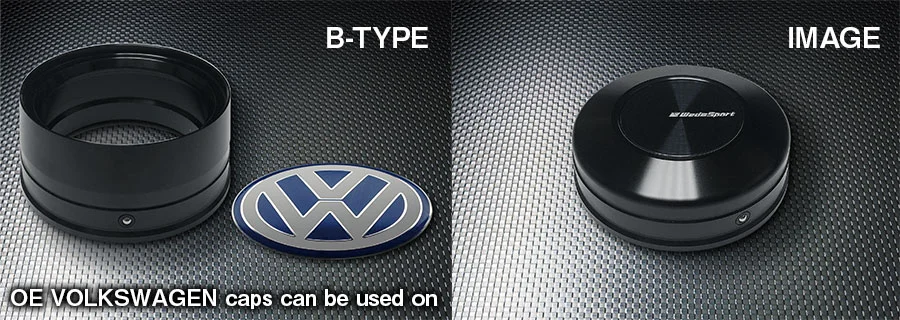

STANDARD TYPE

For use with PCD 100

[#52058]

For use with PCD.114.3,120

[#52059]

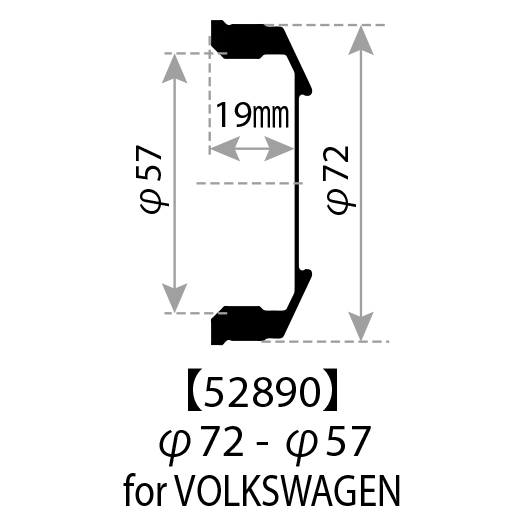

REPAIR PARTS

Light Alloy Valve - BLACK (# S41A2CB)

The technology accelerates sports wheel evolution

AMF (Advanced Metal Forming) is one variation of the rotation forming process that rotates a metal pipe axis and casts the material on the roller.